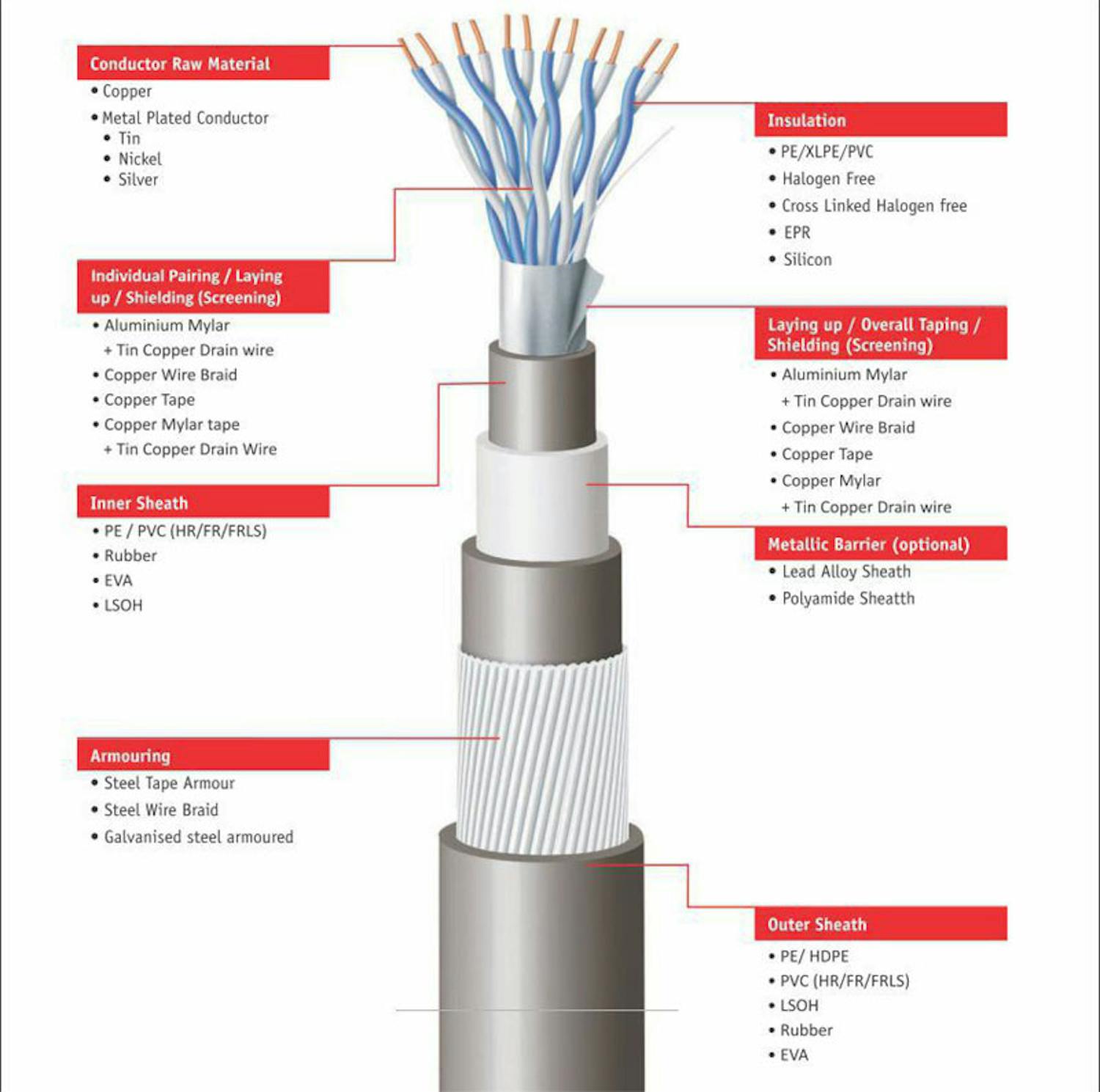

Cable Construction, Performance & Raw Material

Conductor

The metallic part of the cable which conducts the electricity is called

conductor. In case of instrumentation cable it is invariably of copper as

- It has got better conductivity (Next to silver)

- It is free from oxide film in normal atmosphere.

- It is ductile and does not easily break when bent sharply. It can be drawn in to fine wires (45swg)

- It can be soldered easily

Copper has got affinity for sulphur and hence where sulphur is present it should be protected by tinning.. ALL regular rubber cable has sulphur added in rubber for vulcanization and hence tinned copper conductors are always used i.irubber cable. In bigger sized ca Le a seperator tape is applied on bare copper conductor to prevent it from ;Ion–ling into contact with sulphur in rubber.

Conductor for high temperature rating i.e PTFE and FEP insulated cable is of silvered copper to protect the copper from oxidation at higher process and operating temperature (About 200C).

In case of compensating cable the conductor material depend upon its type. This is discussed in detail in section Themocouple Extension Cable & Compensating Cables,

Conductor Construction

In general any one of the following conductor constructions is employed for conductor.

- 50 sq.mm conductor there will be one Wire of 1.38 mm diameter and it is denoted as 1/L38 mm

- STRANDED (Class 2): The conductor is made of several wires (strands) laid up together. Here six strands are laid around one central strand. For 1+50 so.rnm conductor there will be 7 strands of 0+53 mmidia.each and it is denoted as 7/0.53 rnm

- FLEXIBLE (class 5) The conductor is made of several wires twisted together in one direction te for 1..50 sq,mm there will be 30 wires of 0.25 mm dia. each and it is denoted as 30/0.25 mrn.

For read more about Instrumentation Cables please click on the link